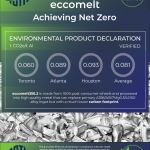

Our new EPD numbers have been verified, and Eccomelt has achieved an even lower carbon footprint than in the past years due to a few key changes in our process. In Georgia, we’ve made incredible progress, dropping from 0.175 tons CO2e/ton of Al to our current 0.089 tons CO2e/ton of Al, as a direct result, among others, of opening our Houston plant. Our strategic new location, along with increased near-sourcing has enabled us to reduce the emissions of incoming logistics, the lion share of our total carbon footprint.

Moreover, the energy mix of the electricity we are sourcing has shifted to more renewable sources, which is an additional factor in our incredibly low numbers. In Georgia, our energy provider has been transitioning to a focus on renewables, and increasing natural gas, which has contributed to our success at continuous improvement.

Our Houston plant has a first time calculated carbon footprint at 0.093 tons CO2e/ton Al, still incredibly low, and as our newest plant, will now be the focus of our efforts. Our Houston plant’s biggest advantage is that it enables us to near-source and produce for our Mexican customers, which has a tremendous impact on our outbound logistics which is not represented in these numbers, as they are cradle to gate.

And let’s not forget our Toronto facility, which already was incredibly low, at 0.089; now we are even lower at 0.06, as we have improved our incoming logistics, through near-sourcing and maximizing rail vs truck transport.

With a combined average of 0.081 tons of CO2e/ton Al, cradle to gate, we are now even lower than we were in our previous assessments. Join our partners and customers and achieve net zero through maximized use of eccomelt356.2 in your products.

Please access the certificates page to read the full EPD report.