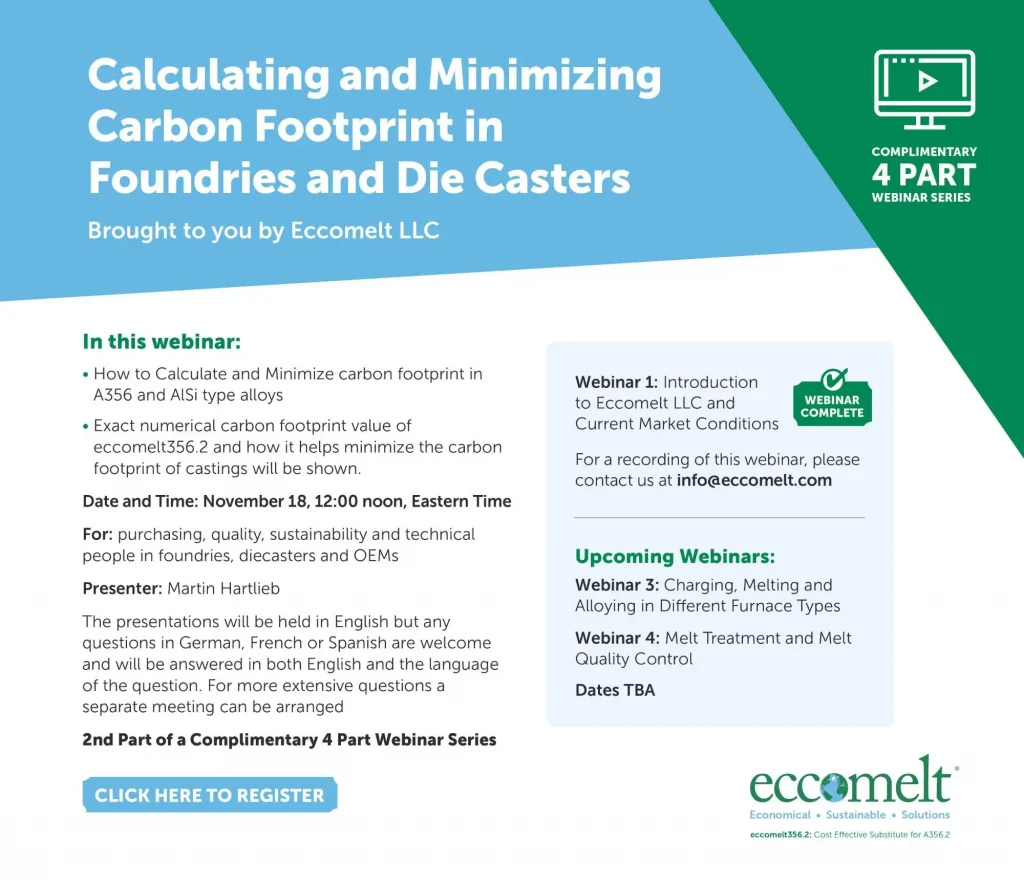

Eccomelt LLC’s latest webinar series, broadcast in North America on Oct. 21, had an informative start with a timely synopsis of current market conditions in the aluminum industry. Beginning with an introduction to the company, the Eccomelt team delivered an overview of the challenges facing many companies in a post-Covid marketplace. CEO Dan Bitton first presented current news about Eccomelt LLC, including photographs of all locations including the newest plant in Houston, Texas. He also provided a review of the aluminum industry’s initiatives that are aimed at achieving a decarbonized, energy efficient, and circular aluminum value chain by 2050. Bitton explained that of the three pathways to reach this goal, Recycling and Resource Efficiency will have the most impact in the near future, with eccomelt356.2 leading the way as its quintessential product. Zulf Karim, COO of Eccomelt, provided a concise explanation (with visuals) of how eccomelt356.2 has possibly the lowest carbon footprint of any aluminum alloy on the market today, and thereby proved Eccomelt LLC’s commitment to sustainability. He further elaborated on the advantages of eccomelt356.2, including its consistent chemistry, surface and internal cleanliness, and its energy efficiency. Martin Hartlieb, the keynote speaker, corroborated Bitton and Karim’s statements, by showing proof of the rigorous technical and quality testing performed by the CMQ on eccomelt356.2, that yielded excellent mechanical properties. The presentation was aided by graphs and pictures which revealed the results of surface cleanliness testing, melting, molten metal analysis (chemistry, hydrogen and inclusion content with RPT, ALSCAN and PoDFA), and tensile testing of T6 heat treated sand and permanent mold castings, all of which confirm the Eccomelt advantage. Hartlieb then discussed current market conditions, beginning with an explanation of Covid related delays and interruptions and how they have affected supply chain distributions and freight rates. The automotive chip shortage was specified as an example of disruptions in the industry and how they have impacted casting and metal demand. Hartlieb then reiterated how sustainability has become the major topic worldwide alongside energy availability and costs, which have also become big issues. As we know, aluminum and silicon (as well as Magnesium) production are extremely energy intensive, which exacerbates the challenge to procuring these commodities. As a result of China curtailing its production of aluminum, silicon and magnesium due to power cuts, there is now a tight supply in North America and Europe, with resultant high prices. In fact, aluminum prices are at a 13 year high, and aluminum scrap supply is short. Mr. Bitton concluded the webinar with the confidence that Eccomelt LLC’s eccomelt356.2 can help the aluminum and automotive industry ride out the stormy market conditions. Indeed, eccomelt356.2 is produced locally in North America, close to where major consumers are, which helps mitigate freight costs and availability risks. Also, it can be delivered reliably within hours or a few days, which has been helping customers avoid plant shutdowns because of metal shortages. Perhaps most importantly, eccomelt356.2 is the lowest energy intensive metal with the lowest carbon footprint in the market, and an economical alternative to primary A356.2, and basis for many Al-Si-Mg type structural alloys. Clearly, eccomelt356.2 is a metal that can help foundries and die casters meet quality, economic and sustainability targets. Please contact info@eccomelt.com for a more information about this webinar, and please check our website for a link to register to our upcoming webinar entitled “Calculating and Minimizing Carbon Footprint in Foundries and Die Casters”.

Please click on the link below to register for the webinar.

https://us06web.zoom.us/webinar/register/WN_gMo9sI1bRWGalAH1ng-S2Q