A new study on the corporate and product carbon footprint of eccomelt356.2 conducted by ClimatePartner GmbH for the full calendar year 2019, provides further confirmation of the product’s extremely low carbon footprint. Climate Partner, a multi-national team of climate experts hailing from 20 countries, adheres to the most stringent standards when calculating the carbon footprint of their clients. The measurement is based on the world’s most widely used greenhouse gas accounting standards for companies, “The Greenhouse Gas Protocol Corporate Accounting and Reporting Standard” (GHG Protocol Corporate Standard[1]). The standard covers Scope 1 & 2, direct and indirect emissions for both facilities, and the all-inclusive Scope 3 standard[2] that covers all indirect emissions from the entire value chain, including raw materials. ClimatePartner calculated both the corporate carbon footprint (CFF) and the product carbon footprint (PCF) of Eccomelt LLC and eccomelt356.2, conducted a full data validation, and identified and applied emission factors from scientific life cycle assessment databases, such as Ecoinvent and GEMIS, as well as their own database.

Following on the heels of Eccomelt LLC’s highly successful webinar, “Lowering your Carbon Footprint in Foundries and Die Casters”, presented by Martin Hartlieb, the ClimatePartner study further consolidates eccomelt356.2 as perhaps the lowest carbon footprint aluminum alloy on the market today. For automotive companies, foundries and die casters looking to reach carbon neutral status by 2050 or earlier, eccomelt356.2 is the obvious choice.

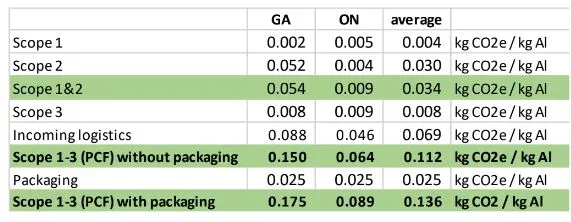

Indeed, the results provided by ClimatePartner are very similar to the numbers calculated by Mr. Hartlieb and McGill University last year, and provide further delineation of Scopes 1-3 and packaging options. eccomelt356.2 is often shipped either loose or in packages, it is necessary to calculate the carbon footprint of either option, leaving the decision to customers as to which suits their needs best. See below for the summary:

The Product Carbon Footprint of eccomelt356.2 is shown in the following table:

The average Scope 1 & 2 is at the very low level of only 0.034 kg of CO2e/ kg Al, which is basically one percent of the equivalent “low carbon primary aluminum” footprint, with the electricity source accounting for the difference between the two production sites, as there is more renewable energy in Ontario than in Georgia. The difference in the incoming logistics of the wheels can be explained by the fact that in Canada long distance shipments are usually sent by train, while almost all shipments in the US are sent by truck, which generate higher emissions than trains. The average carbon footprint, cradle-to-gate, without packaging and transport to a customer’s facility, is 0.112 kg CO2e / kg Al – as seen in the webinar. If the carbon footprint of the supersacks (of about 0.025 kg CO2e / kg Al) is added, the product carbon footprint (cradle-to-gate, Scope 1-3) is 0.136 kg CO2e / kg Al for eccomelt356.2, well below 1% of the global average primary aluminum carbon footprint.

The innovation of eccomelt356.2 lies mainly in its proprietary, non-thermal process, which eliminates one carbon-intensive melting step. The process also provides an extremely clean metal, with minimal dross, and allows for high density to maximize furnace and transportation efficiency. Eccomelt LLC, located in both the US and Canada, is available to provide economical, extremely clean, chemically pure aluminum. Alongside Alcan R&D, Eccomelt LLC has developed a patented process that produces a specification alloy from aluminum wheels at a lower cost than traditional methods and creates a CLEAN CHARGE. eccomelt356.2 is a direct substitute for A356.2 primary aluminum, used by OEMs, Tier 1s, foundries, and die casters who are using eccomelt356.2 to cast high-quality automobile parts. Eccomelt LLC ships products to automotive OEMs and foundries within North America including the United States, Canada, and Mexico, and worldwide, such as France, Ireland, Italy, Serbia, Spain, Hungary, and the Czech Republic.

[1] https://ghgprotocol.org/sites/default/files/standards/ghg-protocol-revised.pdf

[2] https://ghgprotocol.org/sites/default/files/standards/Corporate-Value-Chain-Accounting-Reporing-Standard-EReader_041613_0.pdf