Sustainability

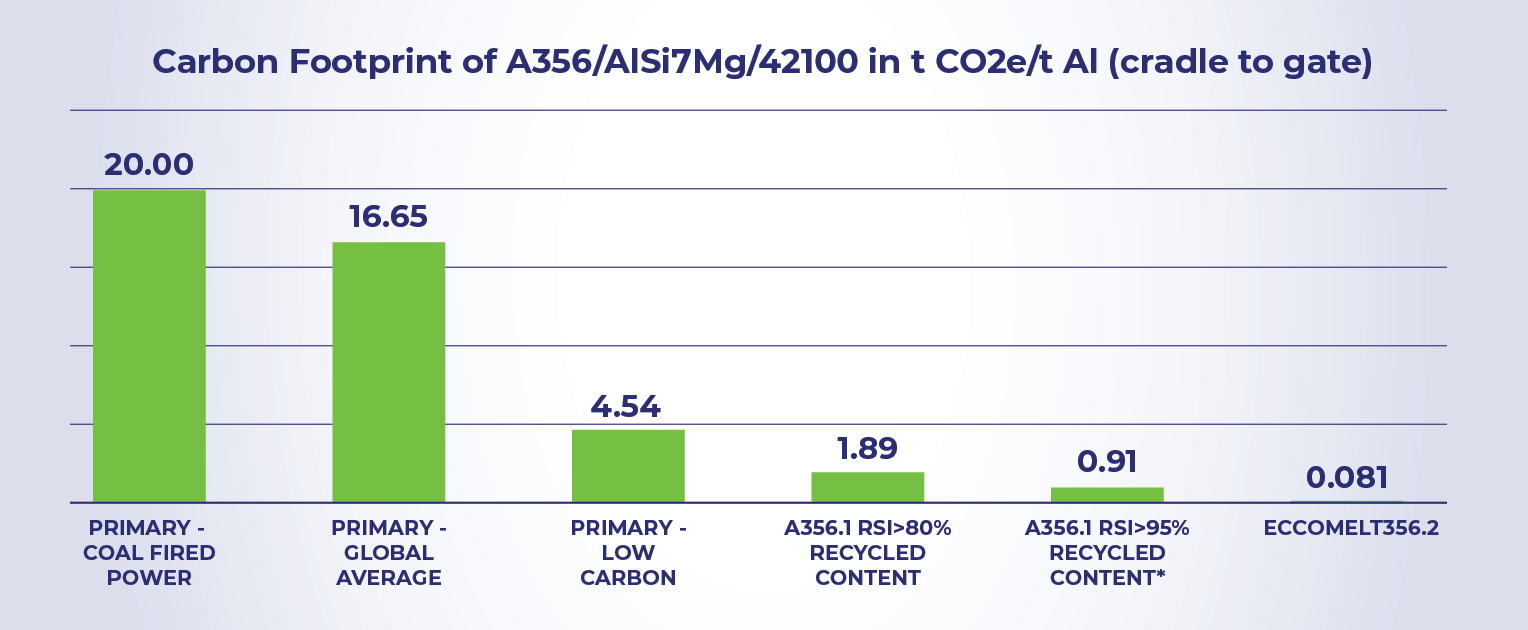

eccomelt356.2 helps your foundry hit its sustainability targets without compromising production. Made from post-consumer aluminum, it delivers up to 95% lower CO₂ emissions compared to primary ingot—while matching the performance of A356.2. With the extremely low EPD number of 0.081, eccomelt356.2 supports circular economy goals, cuts Scope 3 emissions, and comes with full traceability and carbon footprint documentation. If your foundry is looking to decarbonize its supply chain and lead in sustainable manufacturing, eccomelt356.2 is a smart, scalable solution. By integrating eccomelt356.2 into your foundry’s feed, you are realizing the goal of approaching net zero.

We are in the midst of a tremendous shift towards a circular economy, where lowering our carbon footprint to meet the standards of zero carbon emissions protocols is of the utmost importance. Eccomelt remains the frontrunner in the quest for the most energy efficient way to process aluminum, and our product leaves one of the lowest carbon footprints of any primary or secondary aluminum alloy.

0.081 t CO2e/t Al

Cradle to Gate – ISO 14025:2006 and EN 15804

100%

Post-consumer recycled content

<1%

Energy needed compared to primary ingots

The combination of our patented non-thermal cleaning process (avoiding the melting step) and our 100% post consumer content produces an extremely low carbon footprint product.

Due to its unique shape, eccomelt356.2 allows for high density (up to 850 kg/m3, 53 lb/ft3) to maximize furnace and transportation efficiency, so that when our customers melt eccomelt356.2, they are reducing emissions significantly, compared to ingots.

The World's First Carbon Neutral Wheel is made with

eccomelt356.2